Galeria Copper Naranjo is a family-owned workshop located in Santa Clara del Cobre, Michoacán, specializing in handcrafted Copper, Brass, Zinc, and Aluminum products. With decades of traditional experience passed down through generations and a team of over 50 expert artisans, we create customized tabletops, sinks, bathtubs, range hoods, mirror frames, lighting, and décor. We provide trusted OEM & ODM services to brands worldwide, delivering premium finishes, unique textures, and authentic Mexican craftsmanship.

About Us

Galeria Copper Naranjo is a family-owned Mexican workshop located in

Santa Clara del Cobre, Michoacán — the heart of traditional copper craft.

We specialize in handcrafted Copper, Brass, Zinc, and Aluminum products,

offering fully customized OEM & ODM production for global brands.

Our team creates premium tabletops, sinks, bathtubs, range hoods, lighting,

décor, and architectural elements using centuries-old hammering techniques.

Every piece is handmade by skilled artisans, ensuring authentic textures,

premium finishes, and reliable long-term performance.

Years of Experience

Skilled Artisans

Tabletops Per Month

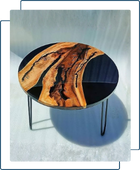

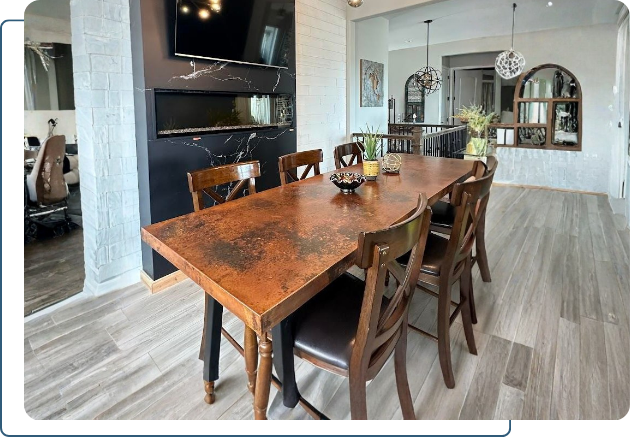

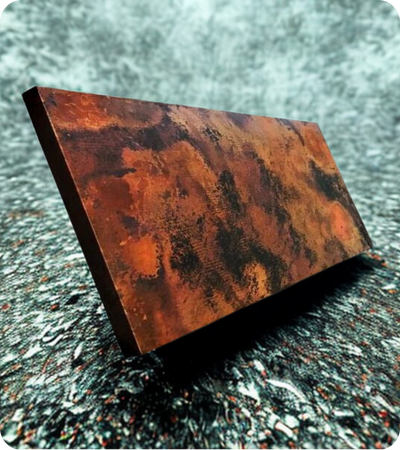

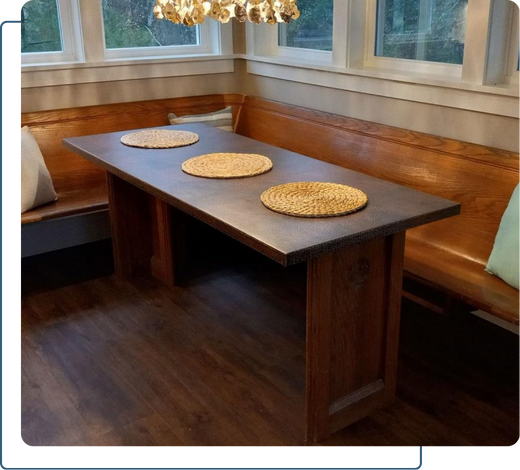

Our Products

Premium handcrafted copper tabletops with custom finishes.

Handcrafted metal bathtubs with premium finishes.

Durable handcrafted metal firepits built for long-lasting outdoor use.

Handcrafted metal firepit tabletops with durable finishes.

Custom metal firepit tabletops crafted with durable finishes.

Handcrafted metal mirror frames made with premium finishes.

Why Choose Us

With decades of experience, we are specialists in copper, brass, zinc, and aluminum product development for global markets.

From tabletops to furniture components, every piece is crafted with strict quality standards, tailored to meet client specifications.

Client Satisfaction

OEM Metal Manufacturing

Specialized in Copper, Brass, Zinc & Aluminum

Design Support & Development

Concept-to-product solutions for custom metalwork

Product Customization

Custom sizes, textures & finishes for global brands

Testing & Quality Assurance

Finish, hardness & durability testing for export quality

R&D & Innovation

New metal finishes, patinas & structural engineering

Objective: To deliver world-class OEM manufacturing in copper, brass, zinc, and aluminum products for global buyers and brands. With over 40+ years of experience in metal craftsmanship, we produce premium tabletops, metal sheets, furniture accents, and custom components at export quality standards.

Approach: Our production process combines hand-crafted finishing with advanced machinery to achieve precision, durability, and consistency. Each product goes through strict metal finishing, patina treatment, thickness checks, and international quality inspections to ensure long-lasting performance.

Outcome: Global OEM partners receive high-quality metal products with accurate specifications, premium finishes, and reliable delivery timelines. Our craftsmanship and capability have helped us build long-term relationships with clients across the USA, Europe, and worldwide.

Objective: To assist global brands in creating unique metal products with premium handcrafted finishes, custom patinas, textures, and structural designs that match their brand identity.

Approach: Our development team works on finish sampling, metal texture creation, custom patina development, 3D modeling, and prototype building . Every design is tested for color consistency, finish durability, and structural strength before moving to full-scale production.

Outcome: Brands receive fully customized, market-ready metal products that maintain high aesthetic appeal, performance, and long-term durability. Our design support has helped international clients launch exclusive collections in furniture, hospitality, and luxury décor.

Work Overview

We specialize in crafting high-quality products in copper, brass, zinc, and aluminum , designed for global OEM requirements. From custom tabletops and metal sheets to furniture components and artistic finishes, every piece is produced with precision, durability, and refined craftsmanship.

How We Work

Initial consultation to understand OEM/ODM requirements, including product specifications, load capacity, finishes, and functional needs to prepare the engineering direction.

Requirement & application study

Load capacity & size review

Material and finish assessment

Engineering layout, wireframe structure, tooling requirements, and final selection of metal grade, coating, runners, sliders, and packaging based on the client's needs.

Technical drawings & engineering

Metal grade & coating selection

Mechanism & hardware approval

Finish & packaging customization

Client approval for production

Production takes place under strict OEM quality standards including welding, polishing, coating, assembly, cycle testing, and final QC verification.

Precision manufacturing

Assembly & fitting checks

SGS/ISO quality testing

Final batch inspection, packaging validation, export readiness check, and approval before dispatch to the client’s region.

Final QC inspection

Packaging validation

Dispatch & shipment approval

Our Gallery

FAQ

Yes, we specialize in OEM manufacturing for global brands, supplying high-quality functional storage hardware built with precision engineering, certified quality systems, and durable materials.

Testimonials